Curing process, FAQ

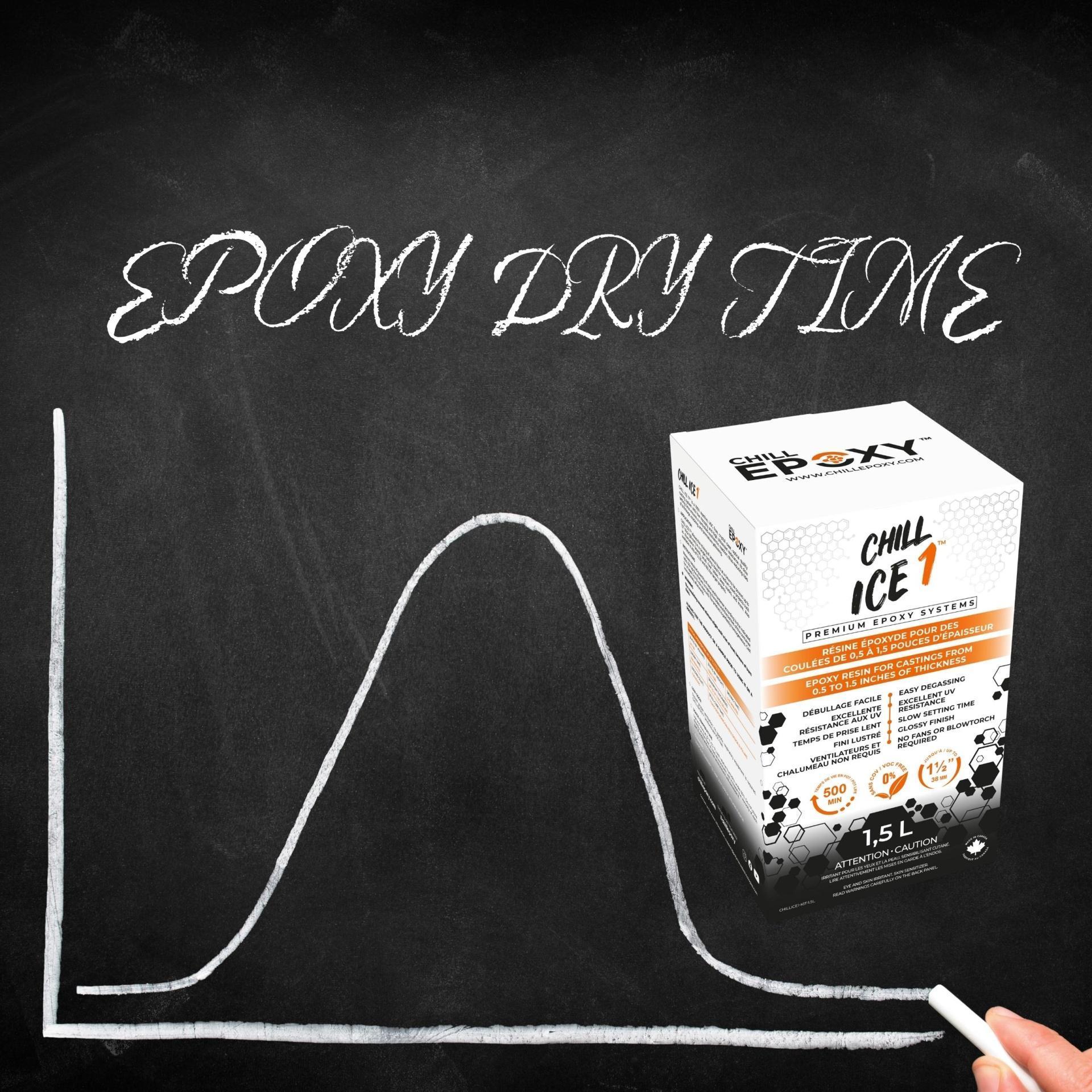

Epoxy Resin Dry Time Pot Life & Working Time

Epoxy resin is a versatile material widely used in various industries such as construction, woodworking, crafting, automotive, and electronics and more. It is an adhesive that hardens to form a solid and durable bond. Epoxy resin is known for its exceptional strength, chemical resistance, and durability, making it ideal for a range of applications. One of the critical aspects of working with epoxy resin is the dry time. In this article, we will discuss the key factors that affect epoxy resin dry time, pot life, and working time.

What is Epoxy Resin Dry Time? Epoxy resin dry time refers to the amount of time it takes for the resin to harden and cure completely. The dry time of epoxy resin is a crucial factor to consider, as it affects the overall strength and durability of the bond.

Factors that Affect Epoxy Resin Dry Time: There are several factors that can influence the dry time of epoxy resin, including:

- Room temperature: Epoxy resin cures faster at higher temperatures and slower at lower temperatures.

- Humidity: High humidity can slow down the curing process, while low humidity can speed it up.

- Type of epoxy resin: Different types of epoxy resin have different curing times.

- Thickness of the resin layer: Thicker layers of epoxy resin take longer to dry than thinner layers.

- Mixing ratio: If the epoxy resin and hardener are not mixed correctly, the curing time may be affected.

Pot Life and Working Time: Pot life refers to the amount of time that epoxy resin remains usable after it has been mixed with the hardener. The working time of epoxy resin refers to the amount of time you have to apply and manipulate the resin before it starts to cure. Pot life and working time are crucial to consider as they determine the amount of time you have to complete your project.

FAQs:

Q: How can I speed up the curing time of epoxy resin?

A: To speed up the curing time of epoxy resin, you can increase the room temperature, use a faster-curing epoxy system, and ensure that the mixing ratio is correct.

Q: What is the average pot life of epoxy resin?

A: The average pot life of epoxy resin is around 30 minutes, but it can vary depending on the type of resin and hardener used.

Q: What happens if I exceed the working time of epoxy resin?

A: If you exceed the working time of epoxy resin, it may start to cure before you have had a chance to manipulate it, leading to an inferior bond.

In conclusion, epoxy resin dry time is an important factor to consider when working with this material. The dry time is affected by several factors, including room temperature, humidity, type of epoxy resin, and thickness of the resin layer. Pot life and working time are also crucial to consider, as they determine the amount of time you have to complete your project. By understanding epoxy resin Dry Time: Factors, Pot Life, and Working Time, you can make informed decisions and improve the quality of your work. Always follow the manufacturer’s instructions and use the right equipment to ensure that your projects are a success. Whether you are a DIY enthusiast or a professional, understanding epoxy resin dry time is essential to achieve the best results. By taking the time to understand these key factors, you can ensure that your projects are completed efficiently and to a high standard.

Epoxy Resin Dry Time: Factors, Pot Life and Working Time

Epoxy resin is a versatile material that has a wide range of applications, including floor and countertop coatings, art and craft projects, and much more. One of the key factors to consider when working with epoxy resin is its dry time, as this can greatly impact the final result of your project. In this article, we’ll take a closer look at the dry time of epoxy resin and how it can be influenced by various factors.

What is the Dry Time of Epoxy Resin?

The dry time of epoxy resin refers to the amount of time it takes for the surface of the resin to dry to the touch. This can vary depending on the temperature and humidity of the room where the resin is being applied, as well as the thickness of the layer of resin. In general, epoxy resin will dry more quickly in warm, dry conditions, and will take longer to dry in cooler, more humid conditions.

It’s important to note that the dry time for epoxy resin is not the same as the cure time. The cure time refers to the amount of time it takes for the resin to fully harden and reach its final strength. This can vary based on the specific product being used, but it’s typically between 24-48 hours for fast-setting epoxy and 4-7 days for slow-setting casting epoxy.

Thickness of the Layer

The thickness of the layer of resin can also play a role in the dry time. A thicker layer will take longer to dry than a thinner one, so it’s recommended to apply multiple thin layers of resin instead of a single thick layer. This will ensure that the resin dries properly and that the final result is consistent and professional.

Chemistry of Epoxy Resin

When part A and part B of the epoxy resin are mixed, a chemical reaction occurs, which creates heat. This heat, created by the friction of the molecules, will cause the resin to harden. The time it takes for this chemical reaction to take place, transforming the resin from a liquid to a solid state, is known as the cure time.

The more mass there is, the more heat is created, and the faster the resin will harden. As a result, a thicker layer of resin will cure faster than a thinner layer. However, it’s important to allow the resin to fully cure before using it or applying additional layers, as this will ensure the best possible outcome.

Pot Life and Reactivity

In addition to temperature and humidity, the pot life and working time of the epoxy resin can also impact the dry and cure times. Pot life refers to the amount of time that the resin remains in a usable state once it has been mixed, while working time refers to the amount of time that the resin remains workable before it begins to harden.

It’s important to check the manufacturer’s instructions for information on the pot life and working time of the specific product you’re using, as this can vary greatly depending on the product. By understanding the pot life and working time of your epoxy resin, you can ensure that you have enough time to work with it and apply it to your project as needed.

In conclusion, epoxy resin is a versatile and popular material for a variety of applications. Understanding the dry and cure times is critical to achieving the desired outcome for your project. Factors such as temperature, humidity, thickness of the layer, pot life, and working time can all impact the dry and cure times. By considering these factors and following the manufacturer’s instructions, you can ensure that your epoxy resin project turns out just the way you want it. So whether you’re using epoxy resin for flooring, countertops, art, or crafts, it’s important to have a good understanding of its properties and behavior.