FAQ, Troubleshooting

Yellowing of the Hardener in Epoxy Resin Causes and Prevention

Yellowing of the Hardener in Epoxy Resin Causes and Prevention

Epoxy resin is a popular material used in a variety of industrial and commercial applications, such as coatings, adhesives, and composites. However, one issue that can arise when using epoxy resin is yellowing of the hardener part B. This can occur due to a variety of factors, including exposure to UV light, high temperatures, and certain chemicals.

When epoxy resin is exposed to UV light, the hardener part B can begin to yellow over time. This is because UV light causes a process called photo-degradation, which can break down the chemical bonds in the hardener and cause it to discolor. Additionally, high temperatures can also cause yellowing of the hardener by accelerating the chemical reactions that take place during the curing process.

Additionally, keeping the epoxy resin in a cool, dry place and away from chemicals can also help to prevent yellowing.

Yellowing of the hardener part B in epoxy resin can also be caused by natural oxidation due to exposure to air. Oxygen in the air can react with the epoxy resin, causing discoloration over time. This is particularly true for epoxy resins that contain unsaturated double bonds, which are more susceptible to oxidation.

This process is called “oxidative curing” and it happens when the oxygen in the air reacts with the epoxy resin and the hardener, causing the hardener part B to turn yellow. The yellowing is more pronounced on the surface of the epoxy, where the oxygen can reach more easily.

Preventing Yellowing in Epoxy Resin: Tips for Maintaining the Quality of the Hardener Part “B”

Closing the hardener container tightly after use can help to prevent oxidation by air and yellowing of the part B. By keeping the hardener in an airtight container, you can reduce the amount of oxygen that comes into contact with the hardener, which can slow down the oxidation process and help to prevent yellowing. Closing the container right after use can also help to prevent the hardener from absorbing moisture from the air, which can also cause yellowing or contamination of the resin.

It’s important to note that once the hardener has been exposed to air, it can start the oxidation process, so it’s recommended to use the hardener as soon as possible, and store it in a cool, dry place.

Additionally, if the hardener container has been opened and exposed to air, it should be used within the time frame recommended by Polymeres Technologies, as prolonged exposure to air can speed up the oxidation process.

Yellowing of the hardener part B can tend to occur faster with more reactive epoxy systems. The more reactive the epoxy system is, the faster the curing process occurs, which can lead to more rapid discoloration due to the increased rate of oxidation.

Epoxy systems that have a faster cure time tend to have a higher exotherm, which means that they generate more heat during the curing process. The heat generated during the curing process can cause an acceleration of the oxidation process, leading to faster yellowing of the hardener part B.

Additionally, more reactive epoxy systems tend to have higher amounts of amines, which are more susceptible to oxidation. This can also contribute to faster yellowing.

It’s worth noting that the yellowing caused by the oxidation process is not only affected by the reactivity of the epoxy but also by the environmental conditions where the epoxy is exposed, such as UV light, temperature, and humidity, as well as the presence of certain chemicals.

Yellowing of the hardener part B in epoxy resin can doesn’t affect the properties of the hardener.

In general, yellowing of the hardener part B can indicate that the hardener has been degraded by exposure to UV light, high temperatures, or certain chemicals. The yellowing is purely cosmetic, and the cured epoxy will have similar mechanical properties, but the yellowing may be noticeable in the final product, especially with clear casting. But, if the yellowing is significant, it can affect the cosmetic properties.

It’s worth noting that yellowing caused by oxidation is a natural process that happens over time, and can be affected by the environmental conditions and the reactivity of the epoxy system. However, it’s possible to prevent or minimize the yellowing by using UV-stabilizers, inhibitors, and storing the hardener in a cool, dry place and using it as soon as possible

It is possible to use a purple pigment to mask or “cut” the yellowing of the hardener part B in epoxy resin.

When the hardener part B yellowing is caused by UV light, high temperatures, and certain chemicals, using purple pigments can mask the yellow color.

Additionally, the color of the final product will be affected by the color of the pigments used and the amount added, it may not match the desired color and could end up looking uneven.

It’s worth noting that to achieve a good cosmetic result, a large amount of pigment may be required, which could affect the final properties of the cured epoxy, such as its mechanical and chemical properties.

It’s important to prevent yellowing by using UV-stabilizers and inhibitors, storing the hardener in a cool, dry place and using it as soon as possible, and controlling the curing environment.

Most cheaper brands may use pigments to mask the yellowing of the hardener part B caused by poor quality of their raw materials which rapidly yellow. It is a common practice to add purple pigments to their part A to an excessive amount and coloration but it’s not a long-term solution to the problem.

The use of metal containers over plastic jugs for maintaining the Quality of the Hardener Part “B”

The metal containers used for the CHILL EPOXY products preserve the hardener better than clear/translucent plastic jug, as metal is less permeable to gases, such as oxygen, than plastic. This means that less oxygen will be able to penetrate the container and reach the hardener, which can help to slow down the oxidation process and prevent yellowing.

Additionally, metal containers are more resistant to high temperatures, which can help to prevent yellowing caused by heat. Metal containers also tend to be more durable and resistant to impacts and scratches, which can help to preserve the quality of the hardener over time.

However, it’s worth noting that the preservation of the hardener also depends on the type of metal used, the quality of the container, and the conditions in which the container is stored. Some metals can react with the hardener and cause discoloration, so it’s important to consult with the manufacturer of the hardener to know if the metal container is appropriate for the hardener.

It’s also important to ensure that the metal container is airtight and properly sealed to prevent air and moisture from entering the container, which can cause yellowing of the hardener.

In summary, a metal container will preserve the hardener better than a plastic jug, but it also depends on the type of metal used, the quality of the container, and the conditions in which the container is stored.

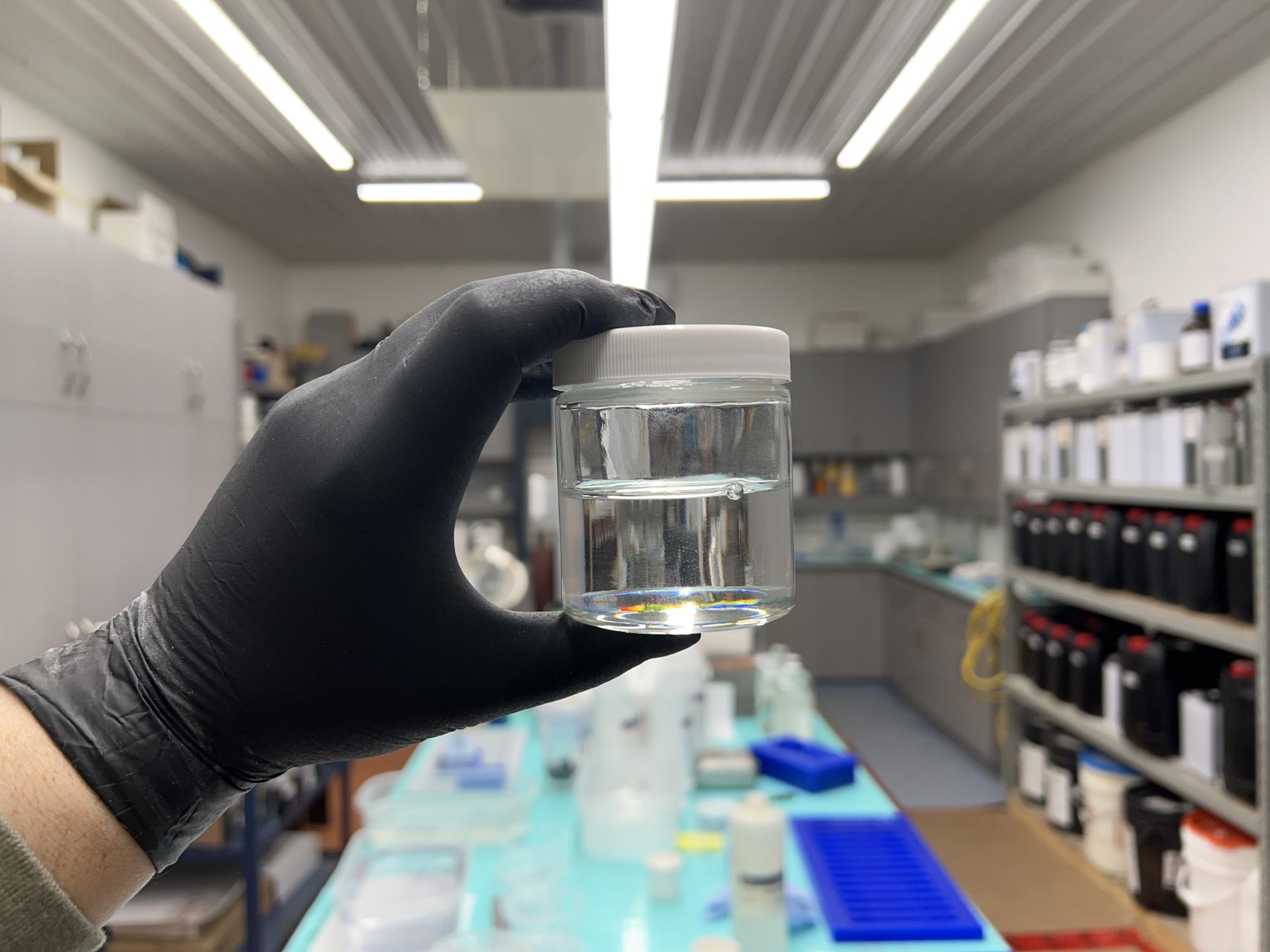

R&D to understand and Prevent Yellowing of the Hardener Part “B”

Manufacturers like Polymeres Technologies with 25 + years of experience with resins that produce high-quality products will typically focus on prevent yellowing by using premium raw materials from well known manufacturers, UV-stabilizers, inhibitors, and other methods to ensure that their products are stable and have a long shelf life. They also offer recommendations for storage and use of the product.

It’s worth noting that using pigments to mask yellowing can be considered as a deceptive or misleading practice, as it can give the impression that the product is of high quality when in reality it is not. It’s important for customers to be aware of this potential issue and to research products and manufacturers before making a purchase.

In general, it’s a good idea to choose products from reputable manufacturers who have a good track record, years of producing high-quality epoxy resins, and to follow the recommended storage and usage instructions to ensure that the product maintains its quality over time.

Polymeres Technologies and his QC team are currently in a research and development process to study this phenomenon. We study the reaction of certain raw materials and interactions between them. Our casting epoxy resins surpass the vast majority of products available on the market these days, but we are trying to eliminate this phenomenon. While most brands tend to hide this phenomenon by adding dyes to their Part “A”. We on the other side are working closely with the biggest raw materials manufacturers to reduce the yellowing of Hardeners.

Our Chemists are working closely with those manufacturer to test new avenues. As you will understand, cheaper raw materials will tend to yellow faster than the expensive ones. This is why we only formulate our epoxy systems with the best raw materials. Coming from a R&D background, our business model has always been to offer superior products and never to cut our prices to offer commodity products.

Moreover, this is why we package our products in Italian Metal containers, instead of cheap plastic “gallon” containers. Plastic breathes, therefore air will get in contact with the Hardener easily and accelerate the process. Metal containers with our double seal cap will keep our epoxy fresh and unexposed to UV.

At last, we package our epoxy both Part “A” Resin and Hardener “B” with Nitrogen Blanket to preserve the epoxy longer ” Unopen” and slow down the yellowing process.

In conclusion, yellowing of the hardener part B in epoxy resin can occur due to exposure to UV light, high temperatures, certain chemicals, and natural oxidation caused by exposure to air. Yellowing can also occur more rapidly in more reactive epoxy systems, due to the increased rate of oxidation. While yellowing doesn’t affect the overall performance of the epoxy, it is mostly a cosmetic issue. To prevent yellowing, it is important to store the hardener in a cool, dry place, and control the curing environment.

Thank you for reading this text on yellowing of the hardener part B in epoxy resin. We hope that you found it informative and helpful. If you have any further questions or would like more information on this topic, please do not hesitate to contact us. We would be happy to assist you.