Clear & Durable Garage Epoxy Concrete Floor Coating | Transparent Topcoat | High-Gloss | 15L Kit ( 3.96 gallons) | TECHNO COATING

USD$258.98

TECHNO COATING is a durable High-Performance Transparent Epoxy Coating for Garages. This VOC Free & low viscosity clear coating solution is ideal for use in industrial and commercial settings. Its low viscosity allows for easy application by gravity, roller or squeegee, saving time and labor costs. It provides a smooth and seamless surface that is easy to clean and maintain, improving the overall appearance of the floor. It has excellent properties, including superior mechanical properties such as high strength, abrasion resistance, and impact resistance. This coating offers an impeccable aesthetic finish that can enhance the image of the facility and provide long-lasting protection to the floor.

This High-performance epoxy resin floor coating offers superior hardness, making it ideal for commercial and industrial applications.

In stock

U.S. orders may experience slight delays.

All shipments are fulfilled from our U.S. warehouse —

no extra fees or surprise invoices.

U.S. orders may experience slight delays.

All shipments are fulfilled from our U.S. warehouse —

no extra fees or surprise invoices.

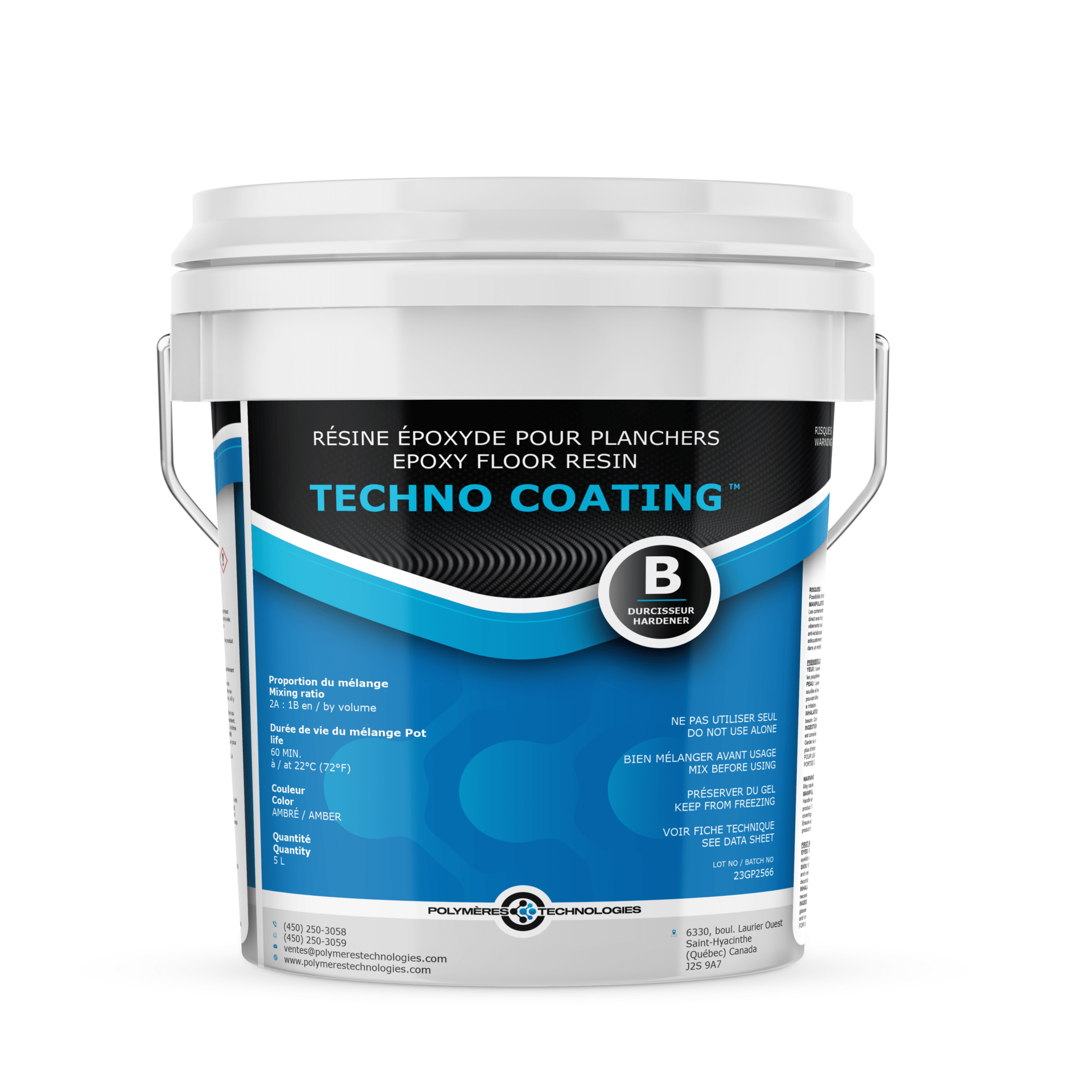

Clear & Durable Garage Epoxy Floor Coating | Transparent Topcoat | High-Gloss | 15L Kit ( 3.96 gallons) | TECHNO COATING

Clear & Durable Garage Epoxy Concrete Floor Coating. TECHNO COATING™, our premium High-Performance Epoxy Resin Floor Coating. This two-part, 100% solid (VOC free) solution is specially formulated to provide a clear and glossy finish on interior surfaces such as concrete floors. Its low odor formula makes it easy to use and ideal for both commercial and residential applications. The best feature of our high-performance epoxy resin floor coating is its durability and chemical resistance. It is able to withstand heavy traffic and frequent cleaning, making it ideal for use in industrial and commercial settings. Additionally, it provides a smooth and seamless surface that is easy to clean and maintain, and it can also improve the overall appearance of the floor.

TECHNO COATING™ High-performance epoxy resin floor coating has excellent properties that make it suitable for use in a variety of industrial and commercial settings. IT has superior mechanical properties such as high strength, abrasion resistance, and impact resistance. It also have very good resistance to chemicals, including acids, alkalis, and solvents, making it ideal for use in environments where chemical spills may occur. Additionally, it has an impeccable aesthetic finish that can improve the overall appearance of the floor and enhance the image of the facility.

Clear & Durable Garage Epoxy Concrete Floor Coating

Another benefit of high-performance epoxy resin floor coating. Its low viscosity allows for easy application by gravity, roller, or squeegee. This can save time and labor costs during the installation process. Additionally, the low viscosity allows the epoxy to self-level and fill in small cracks and imperfections in the floor, providing a smooth and even surface. This coating is waterproof, making it suitable for high-moisture areas, and also has good chemical and abrasion resistance. Its excellent resistance to UV radiation makes it perfect for use in areas with high sun exposure. The epoxy coating is easy to clean and maintain, ensuring that your floors will look great for years to come. Choose TECHNO COATING™ for a durable, long-lasting and attractive finish on your floors.

Additionally, it can be used in combination with our CHILL DROPS™ pigments (opaque or transparent) to create amazing colors or special effects

Features:

- Pre-measured unit of 15L Kit ( 3.96 gallons)

- 100% Solid (NO VOC or Solvent)

- 60 Min of Pot Life

- High-Gloss

- Excellent Impact Resistance

- Suitable for in-service areas exposed to the high humidity level

- Available in a multitude of colors based on the CHILL DROPS™ pigment charts

- Very durable

- Low viscosity to avoid bubbles

- Extreme mechanical strength and stress resistance

Characteristics:

- Easy Mixing Ratio: 2:1 by volume – Pre-measured unit of 15L.

- Ideal Working Temperature: 22C /72F

- Pot Time: 160 minutes at 22C/72F

- Cure Time: Touch dry ~8–12 hours at 22°C (72°F), Light traffic ~24 hours at 22°C (72°F), Full cure 7 days at 22°C (72°F)

- Recommended cleaning products: POLY CLEANER™ Resin Cleaner or Isopropyl Alcohol.

Concrete Floor Coating Surface Preparation:

Surface preparation is an essential step in the process of applying a high-performance epoxy floor coating. The surface must be clean, dry, and free of any contaminants such as oil, dirt, or grease before the coating can be applied. The specific steps for surface preparation will depend on the type of surface that is being coated and the condition of that surface.

To prepare the surface, the following steps are recommended:

- Clean the surface using a pressure washer or a degreaser to remove any dirt, dust, or debris. Treat any oil or grease stains with a degreaser specifically formulated for those types of stains.

- Profile the surface using a diamond grinder or a shot blaster to create a rough surface that will help the epoxy adhere better. The profile should be a minimum of CSP 3 (Concrete Surface Profile).

- Repair any cracks or holes in the surface with a concrete patch or repair compound.

- Neutralize any high pH levels in the surface with a phosphoric or muriatic acid solution.

- Allow the surface to dry completely before applying the epoxy coating. Check the moisture level of the concrete with a moisture meter to ensure proper adhesion.

- Tape or mask off any areas that are not going to be coated, such as baseboards or walls, to protect them from overspray.

It is important to follow the manufacturer’s instructions for surface preparation to ensure proper adhesion and desired results. Additionally, we recommend an ambient temperature of 22°C (72°F), relative humidity less than 70% and both TECHNO COATING parts (A/B) at a temperature of 22°C (72°F) for the best results. For more details, please consult POLYMERES TECHNOLOGIES ([email protected])

| Weight | 19.95 kg |

|---|---|

| Dimensions | 55.88 × 33.02 × 48.26 cm |

| Size | Pre-measured unit of 15L |

Only logged in customers who have purchased this product may leave a review.

You may also like…

Related products

Epoxy Resins

Epoxy Resins

Food Safe & Fast Curing Epoxy Sealer | Penetrating Resin | Eco-Friendly | CHILL SEALER | CHILL EPOXY

Epoxy Resins

Fast Setting Clear Epoxy Resin | Small Castings and Repairs | Food Safe Epoxy | CHILL DIAMOND FAST

Flooring Epoxy

Industrial Flooring Clear Epoxy Topcoat Resin | UV-Resistant Epoxy Coating | SHIELD-TEC 803

Reviews

There are no reviews yet.