Ultra Clear & Food Safe Epoxy Resin | Deep Pour Casting Epoxy | Up to 1.5″ thick | CHILL ICE 1

USD$91.98 – USD$9,599.18Price range: USD$91.98 through USD$9,599.18

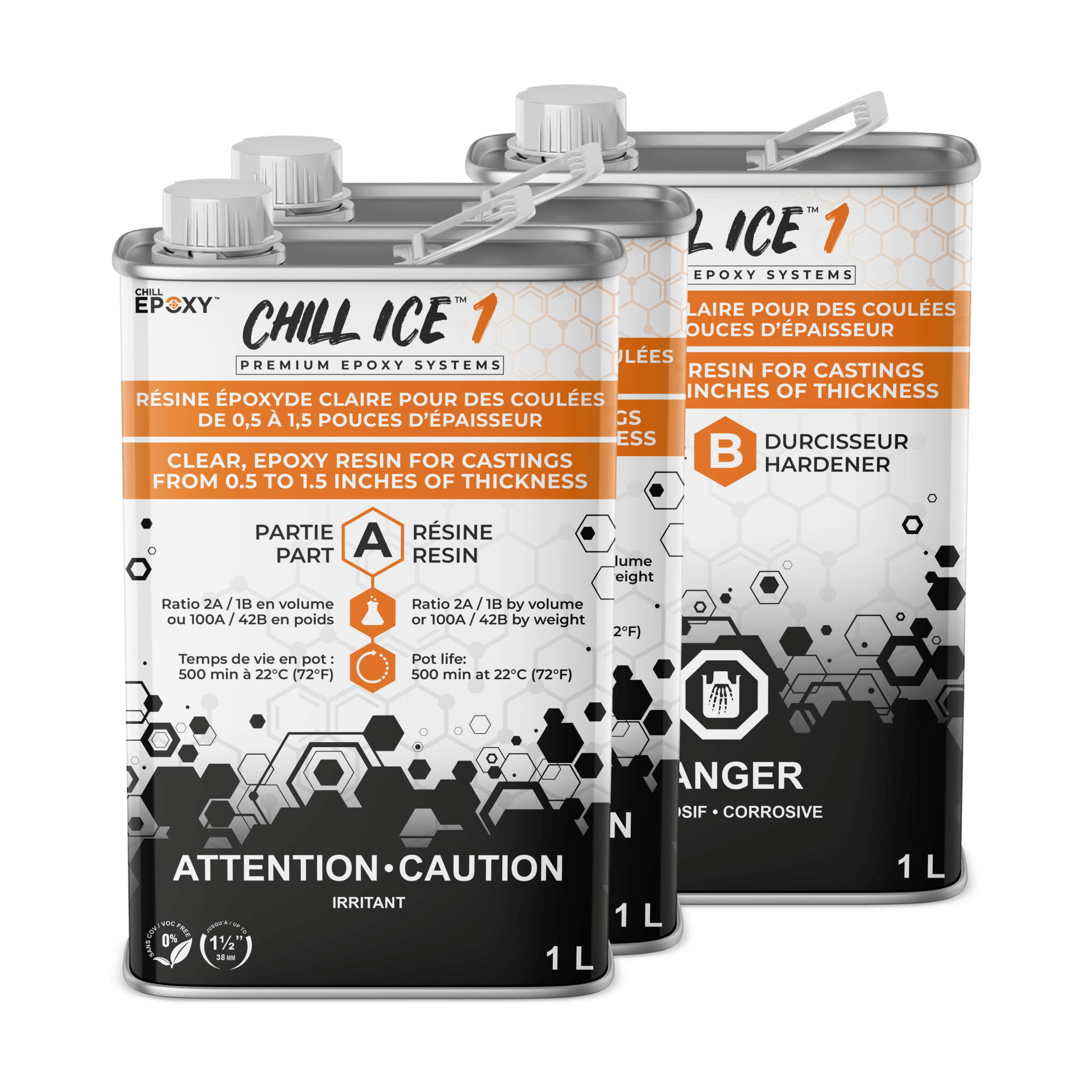

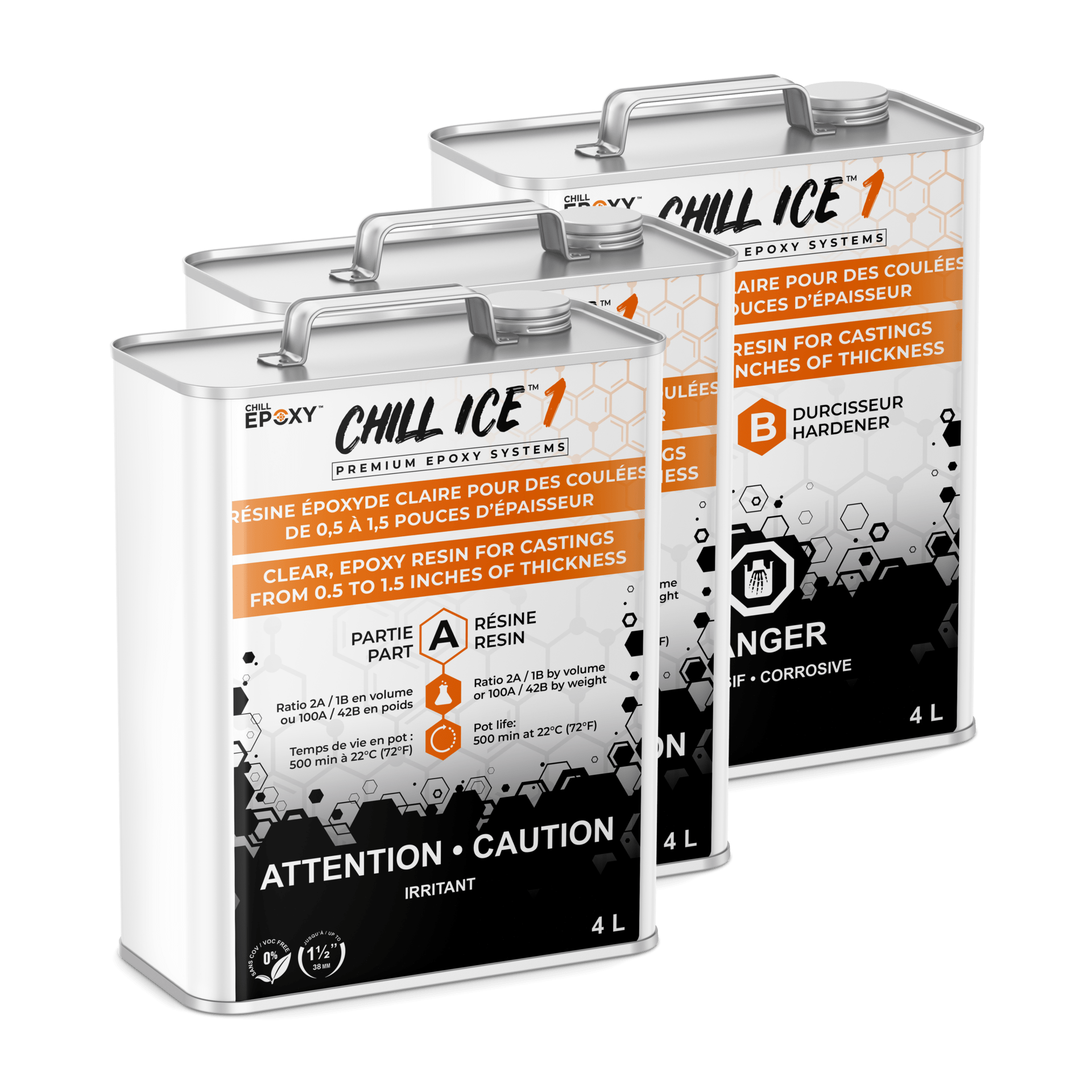

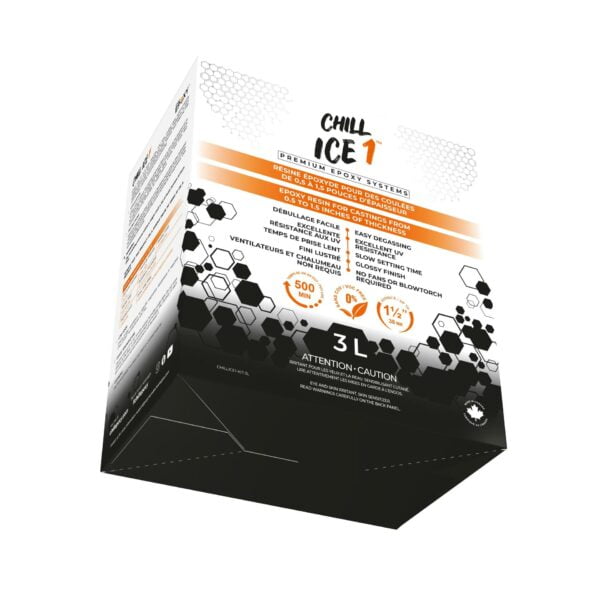

Two-component Clear Deep Pour Epoxy Resin designed with low viscosity raw materials and an extended working time for optimal performance in projects ranging from 1/2″ to 1.5″ thick. Its exceptional flow characteristics ensure bubble-free results, while its very low viscosity and 100% reactive formula enable precise casting of projects up to 1.5 inches thick and 60L in size. The crystal-clear transparency of CHILL ICE 1™ delivers a stunning finish, enhancing the aesthetic appeal of your creations, whether it’s a river table, a coffee table, or any small to medium-size project.

U.S. orders may experience slight delays.

All shipments are fulfilled from our U.S. warehouse —

no extra fees or surprise invoices.

U.S. orders may experience slight delays.

All shipments are fulfilled from our U.S. warehouse —

no extra fees or surprise invoices.

Ultra Clear & Food Safe Epoxy Resin | Deep Pour Casting Epoxy | Up to 1.5″ thick | CHILL ICE 1

Ultra Clear & Food Safe Epoxy Resin | Deep Pour Casting Epoxy | Up to 1.5″ thick | CHILL ICE 1. CHILL ICE 1™ Clear Deep Pour Epoxy Resin for 1/2 – 1.5″ layers – the perfect clear casting epoxy system for your next river table or small to medium-sized project. With its ultra-clear transparency and slow setting, UV-resistant formula, CHILL ICE 1™ is a must-have for all casting enthusiasts.

Are you tired of bubbles ruining your project? Look no further than CHILL ICE 1™, which offers excellent bubble release and a low odor. Its long pot life also allows you to mix and pour large quantities of resin with ease.

But that’s not all. CHILL ICE 1™ has a 100% reactive formula and low viscosity, making it easy to achieve precise results up to 1.5 inches thick and 60L in size. Plus, it is UV-resistant, ensuring the longevity and beauty of your finished project for years to come.

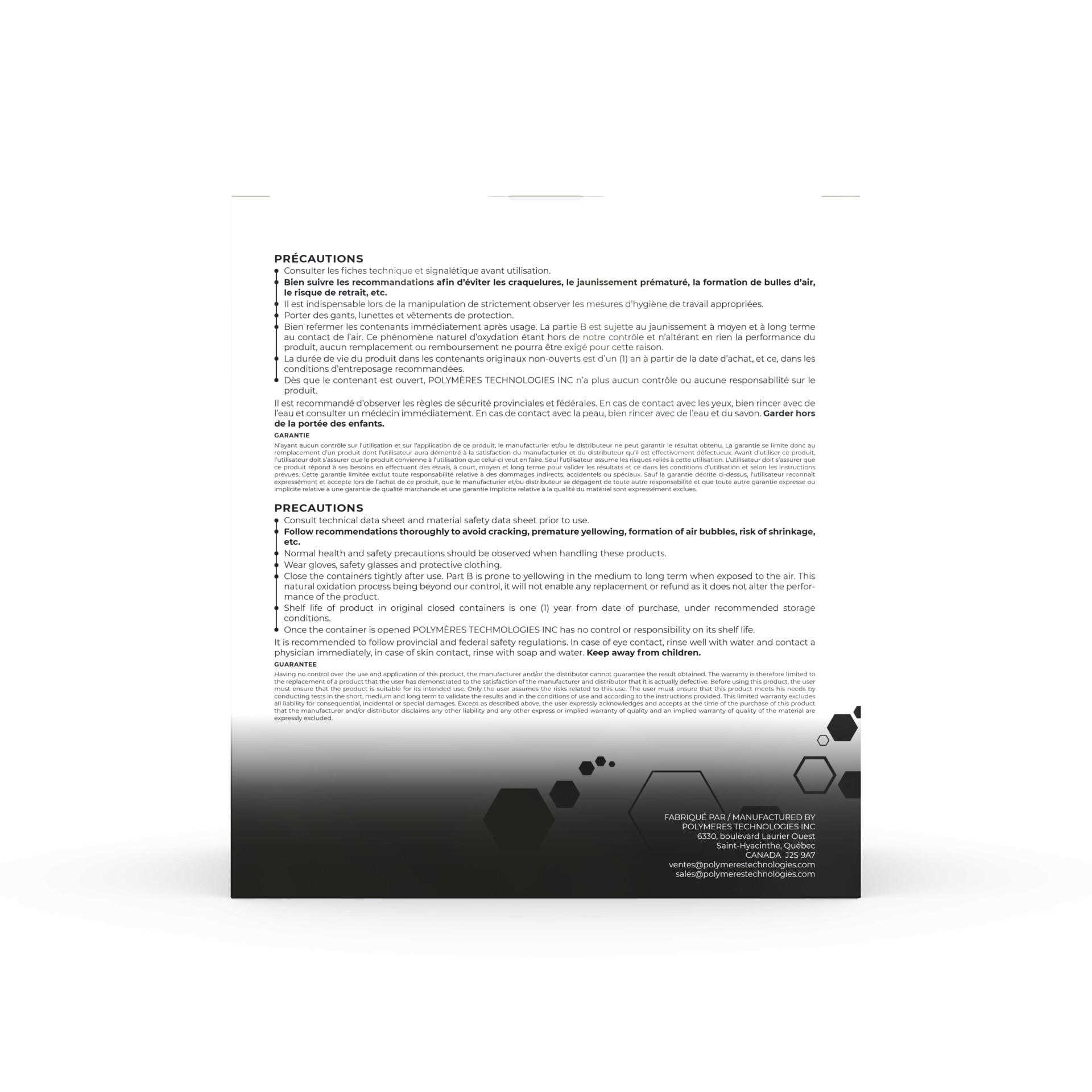

But don’t just take our word for it. Our product meets the European RoHS standard, making it an environmentally-friendly choice for your casting needs. And, with the option to add a touch of color using CHILL DROPS liquid pigments – Transparent or Opaque – you can truly make your project stand out.

In summary, if you’re looking for a clear casting epoxy system that offers excellent bubble release, a long pot life, and UV-resistance, CHILL ICE 1™ is the perfect choice. With its versatility and easy application, you can achieve stunning, bubble-free results in a shorter amount of time, without sacrificing durability. Choose CHILL ICE 1™ for your next project and create something truly beautiful.

Ultra Clear Deep Pour Epoxy Resin 1/2 – 1.5″ layers – CHILL ICE 1™

Features:

- Ideal for projects between 0.5 to 1.5” thick, in a single pour without the need to use a fan.

- It is commonly used for the casting of river tables, coffee tables, or medium-size projects using molds.

- Very durable

- Water like viscosity to avoid bubbles

- Can be colored with one of our CHILL DROPS or metallic pigments.

- Very strong mechanical strength and stress resistance

- High-Gloss

- Self-Leveling

- Heat and Impact Resistance

- Slow setting time

- Low odor

Characteristics:

- Easy mixing ratio: 2:1 by volume or 100/42 by weight

- Ideal working temperature: 22C /72F

- Pot time: 500 minutes at 22C/72F depending on volumes and room temperature

- Cure time: 3-5 days depending on volume, room temperature, humidity level, and thickness of the casting

- Recommended thickness per layer: 0.5-1.5″ per layer.

- Maximum thickness in a single pour: 1.5″ max

- Cure appearance: Optical clarity

- Viscosity: 195 CPS mixed – Very low viscosity for a better penetration

- Recommended cleaning products: POLYCLEANER™ resin cleaner or isopropyl alcohol

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Size | 1.5L, 3L, 6L, 12L, 30L, 60L, 600L |

3 reviews for Ultra Clear & Food Safe Epoxy Resin | Deep Pour Casting Epoxy | Up to 1.5″ thick | CHILL ICE 1

Only logged in customers who have purchased this product may leave a review.

Related products

Epoxy Resins

Crystal Clear & VOC Free Deep Pour Epoxy Resin | 2-3″ Thick River Tables | UV- Resistant

Flooring Epoxy

Industrial Flooring Clear Epoxy Topcoat Resin | UV-Resistant Epoxy Coating | SHIELD-TEC 803

Epoxy Resins

Fast Setting Clear Epoxy Resin | Small Castings and Repairs | Food Safe Epoxy | CHILL DIAMOND FAST

Epoxy Resins

Clear & Food Safe Countertop & Tabletop Epoxy Resin | Scratch-Resistant | Heat-Resistant | CHILL 3D

Epoxy Resins

Food Safe & Low Viscosity Epoxy Resin Top Coat | Woodworking & Crafting Epoxy | CHILL CLEAR

John Loeppky (verified owner) –

Great product from a great team! I find it easy to use and I get a high quality finished product that my customers can enjoy for years to come!

Jean-David Roy –

John,

We’re thrilled to hear that you’re happy with the product and appreciate the team behind it. Providing high-quality finished products that last is always a win! Thank you for sharing your positive experience.

Team CHILL EPOXY ™

jwells (verified owner) –

Great product. Easy to use, poured well and has a crystal clear finish. It also worked out the few bubbles there were on it’s own.

Jean-David Roy –

Thank you, Johnce!

We’re delighted to hear that you had a great experience with our product. Your feedback means a lot to us, and we’re thrilled that you found it easy to use and achieved a crystal clear finish effortlessly. If you have any more projects in mind or any questions, feel free to reach out. We’re here to help!

Team CHILL EPOXY ™

Melissa Miles (verified owner) –

Love the long work time of this resin and how I don’t have to use my vacuum chamber to for bubbles! Nice and crystal clear.

Jean-David Roy –

Thank you, Melissa, for sharing your thoughts on this resin! We’re thrilled to hear that you love the long work time and how it eliminates the need for a vacuum chamber to deal with bubbles. Achieving a crystal-clear finish is essential, and we’re delighted that our product meets your expectations. Your feedback is much appreciated, and we hope you continue to enjoy using our resin for your projects! If you have any more comments or questions, please don’t hesitate to reach out. Happy crafting! TEAM CHILL EPOXY™