Blog, CHILL EPOXY products

Best Epoxy to Use for Charcuterie Boards & Medium-sized Projects

Best Epoxy to Use for Charcuterie Boards & Medium-sized Projects

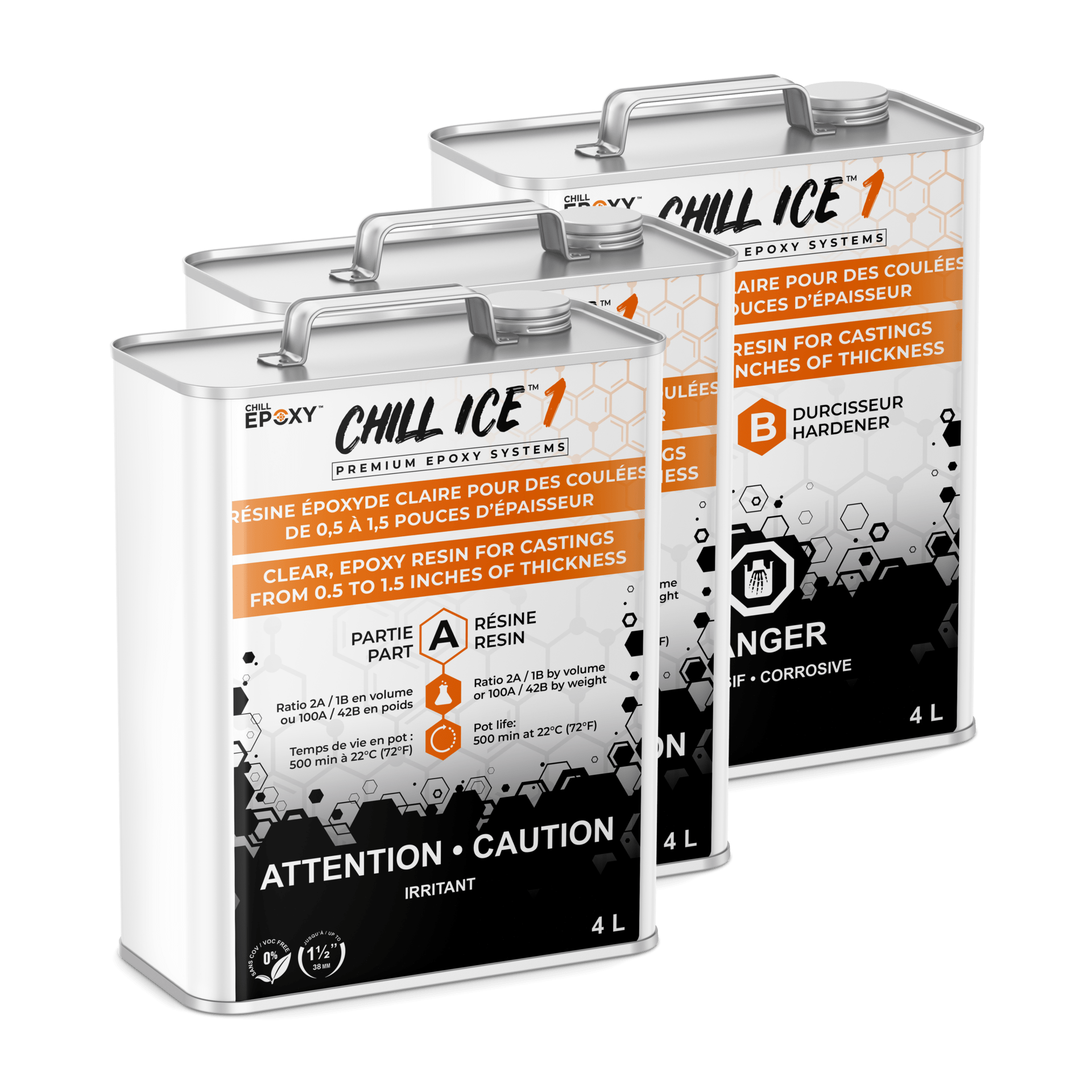

As a chemistry company and resin experts, we often get asked about the best materials to use for various DIY projects. One question that keeps cropping up is “what’s the best epoxy to use when doing charcuterie boards and medium size projects?” In this article, I’ll share my insights on this topic, focusing on the exceptional properties of CHILL ICE 1, a product in the CHILL EPOXY line.

Understanding the Epoxy Resin

Are you curious about the fascinating world of epoxy resin? Look no further! In this article, we will take you on a journey to understand the epoxy resin, a versatile and durable material that has revolutionized various industries. From crafting to construction, epoxy resin has become a go-to solution for creating stunning and long-lasting products. Epoxy resin is a two-component system consisting of resin and hardener. When mixed together, a chemical reaction occurs, producing heat (exothermic reaction) and hardening the mixture into a durable plastic material. However, not all epoxies are created equal. Some key properties to consider are pot life, exothermic reaction control, and curing time.

Importance of Extended Pot Life

Pot life is the working time you have once the epoxy resin and hardener are mixed together before it starts to harden. A longer pot life is beneficial for deeper pours as it allows more time for air bubbles to escape, ensuring a clear, bubble-free finish. This is especially critical when working with pieces that are between 0.5-1.5 inch thick. When it comes to working with epoxy resin for medium-sized projects, one crucial factor to consider is the extended pot life of the material. Pot life refers to the time duration during which the epoxy resin remains in a workable state after being mixed. It is an essential consideration, as it directly impacts the success and quality of your project.

One of the primary advantages of using epoxy resin with an extended pot life is the increased flexibility it offers during the pouring process. Medium-sized projects often require more time for preparation, positioning of materials, and meticulous pouring techniques. With a longer pot life, you have a greater window of time to work with the resin, reducing the need to rush and allowing for a more controlled and precise application.

Controlled Exothermic Reaction

A controlled exothermic reaction refers to a chemical reaction that releases energy in the form of heat, but is carefully managed to prevent uncontrolled or excessive heat generation. Exothermic reactions occur when the reactants in a chemical reaction release more energy than is required to break the bonds within them. This excess energy is released as heat, leading to a rise in temperature. The chemical reaction that occurs when mixing epoxy generates heat. This heat can become problematic in thicker pours as it may lead to overheating and cracking. Therefore, a controlled exothermic reaction that generates less heat is desirable for deeper pours.

CHILL ICE 1: A Superior Casting Epoxy

When it comes to epoxy resins, CHILL ICE 1 truly stands out among its competitors. This exceptional product is a part of the esteemed CHILL EPOXY line and is specifically formulated to cater to the needs of various applications such as serving boards, charcuterie boards, coffee tables, and smaller river tables that are up to 1.5 inches thick.

What sets CHILL ICE 1 apart is its remarkable performance and versatility. Crafted with meticulous attention to detail, this epoxy resin offers a host of benefits that make it a top choice for both professional craftsmen and DIY enthusiasts alike. Its unique composition ensures a crystal-clear, glass-like finish that enhances the natural beauty of the underlying materials, making it perfect for showcasing the intricate patterns and grains of wooden surfaces.

One of the key features of CHILL ICE 1 is its ease of use. It is designed to be user-friendly, allowing even beginners to achieve outstanding results. The resin has a low viscosity, ensuring effortless pouring and self-leveling properties that minimize the occurrence of uneven surfaces. This feature is particularly beneficial when working with serving boards, charcuterie boards, and coffee tables, as it helps to create a smooth and flawless finish that is both visually appealing and functional.

Ideal Use of CHILL ICE 1

With a pot life of 400 minutes, CHILL ICE 1 is a very versatile casting epoxy that can be used for many applications. This extended pot life is excellent for projects that require a deeper pour and a clear, bubble-free finish.

- River Tables: Create stunning river tables by pouring epoxy resin between slabs of wood, creating a beautiful flowing river effect.

- Charcuterie and Serving Boards: Design unique charcuterie and serving boards by pouring epoxy resin onto wooden surfaces.

- Wall Art and Decorations: Make eye-catching wall art and decorations by pouring epoxy resin into molds or onto canvases.

- Encased Objects: Preserve flowers and showcase special items by encasing them in epoxy resin. This could include flowers, shells, photographs, or sentimental objects.

Remember to follow safety guidelines and instructions provided by the manufacturer when working with epoxy resin. With these project ideas, you can explore your creativity and enjoy the versatility of epoxy resin within the recommended thickness range.

Unique Features of CHILL ICE 1

Long Pot Life

Unlike many other brands, CHILL ICE 1 offers an extended pot life, making it easier to work with and less stressful, especially for intricate projects.

No Overheating Issues

One of the key features of CHILL ICE 1 is its controlled exothermic reaction. This means it generates less heat, reducing the risk of cracking and doesn’t require any cooling systems or the use of fans to control the heat.

Unmatched Clarity

If you’re looking to achieve a crystal-clear pour, CHILL ICE 1 is the epoxy for you. Its low viscosity formula allows air bubbles to rise and escape more easily, ensuring a bubble-free project.

Durability and Hardness

CHILL ICE 1 is much harder than most commodity epoxies, thanks to the superior raw materials used in its formulation. This extra hardness means your projects will stand up better to everyday wear and tear.

Environmentally Friendly

Did I mention it’s environmentally friendly too? CHILL ICE 1 is VOC-free, meaning it doesn’t contain any volatile organic compounds that could harm the environment.

CHILL EPOXY: A Line of Exceptional Products

The CHILL EPOXY line offers a range of products suitable for various projects. However, for serving boards, charcuterie boards, and smaller river tables up to 1.5 inches thick, a 2:1 ratio of CHILL ICE 1 is the best option.

2:1 Ratio: The Optimum Choice

The 2:1 ratio refers to the recommended mix of two parts resin to one part hardener. This ratio provides an ideal balance between working time, cure speed, and physical properties, making it the optimal choice for most applications.

FAQs

- What epoxy to use for a charcuterie board? CHILL ICE 1 is an excellent epoxy for charcuterie boards due to its long pot life, controlled exothermic reaction, and superior hardness.

- Is there a food safe epoxy for cutting boards? Yes, CHILL ICE 1 is food safe once fully cured, making it ideal for cutting boards.

- What kind of epoxy is food safe? Epoxy resins, like CHILL ICE 1, that do not contain volatile organic compounds (VOCs) and are fully cured are considered food safe.

- What is the best sealant for a charcuterie board? A clear epoxy such as CHILL SEALER is the best sealant for a charcuterie board. It provides a durable, food-safe finish that enhances the natural beauty of the wood.

- Why is a 2:1 ratio recommended for CHILL ICE 1? A 2:1 ratio provides an ideal balance between working time, cure speed, and physical properties, making it the best choice for most applications.

Conclusion

Choosing the right epoxy can make all the difference in your DIY projects. For charcuterie boards and medium-sized projects between 0.5-1.5 inch thick, CHILL ICE 1, with its long pot life, controlled exothermic reaction, and superior hardness, is an unbeatable choice. Not only does it offer exceptional performance, but it’s also environmentally friendly, making it a win-win for you and the planet.