Blog

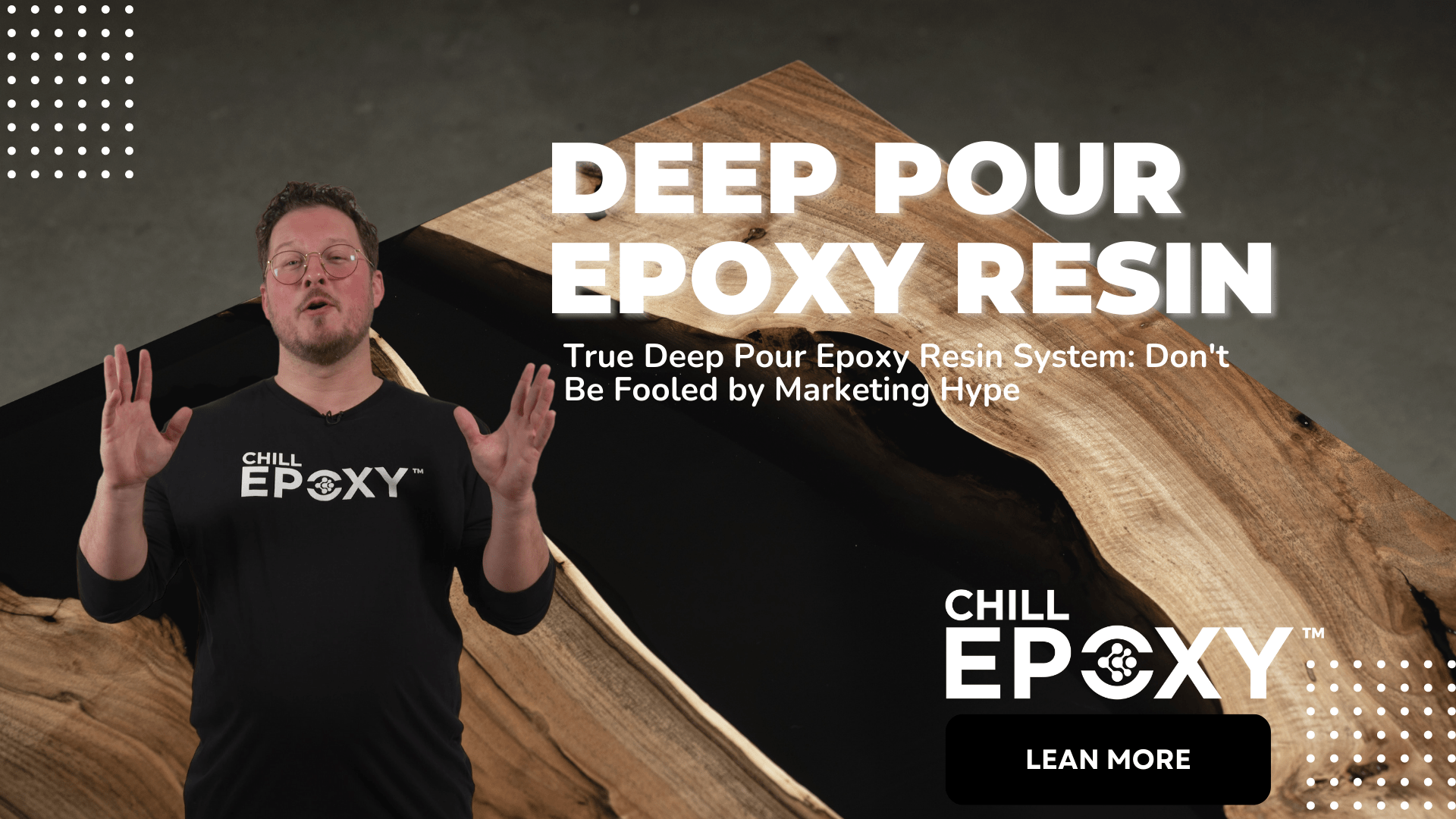

Choosing a True Deep Pour Epoxy Resin System: Don’t Be Fooled by Marketing Hype

True Deep Pour Epoxy Resin System

Epoxy resin has become a popular material in various industries, including woodworking, construction, and art. With the development of deep pour epoxy resin, there are new possibilities for large-scale projects. In this article, we will explore the differences between deep pour and regular epoxy. We will cover the applications of deep pour epoxy, and its potential use as a topcoat. Additionally, we will examine the properties of Slow Cure Casting Epoxy Resin, extended pot life and controlled exothermic reactions.

Don’t Be Fooled by Marketing Hype

Deep pour epoxy resin has become a popular material for large-scale projects, such as river tables and clear castings. However, not all deep pour epoxy resins are created equal. Many repackagers and manufacturers claim that their epoxy casting system is a deep pour system. Unfortunately without providing clear information on the volume they can pour.

A true deep pour system should be formulated with the objectives of being low in viscosity, long pot life, low exotherm curve, and very low shrinkage level.

A real deep pour system can allow for pouring large masses from 50L to 130L from 1 inch thick to 3 inches thick in one single pour, without the need to low down the room temperature or use a torch to get rid of bubbles. It is important to be careful when selecting your deep pour epoxy system, ensuring that it mentions the thickness and mass you can pour up to. If it is not mentioned, it is not a true deep pour system.

At CHILL EPOXY™, we offer a variety of deep pour epoxy resin systems with long pot life, allowing for the pouring of larger masses without overheating or the need to add fans to cool it down. Our deep pour epoxy resin for 2″ thick has a pot life of 600 min, making it ideal for bigger masses at 2″ thick. Our CHILL DEEP POUR™ Casting Epoxy is designed for deeper and wider projects with a considerable mass between 60-100L in a single pour.

What is the Difference between Deep Pour and Regular Epoxy?

The primary difference between deep pour and regular epoxy is the thickness of the application, working time, raw materials, Curing Agents. Regular epoxy is typically applied in thin layers, usually no more than 1/8-1/2 inch at a time. In contrast, deep pour epoxy can be applied in thicknesses up to several inches, making it an ideal material for large-scale projects such as river tables.

Another difference is the chemical composition. Deep pour epoxy has a lower viscosity, allowing it to flow more easily and fill in voids and imperfections. It also has a longer curing time to avoid cracking, shrinkage, or overheating.

What is Deep Pour Epoxy Used For?

Deep pour epoxy is used for various projects that require a thickness of several inches. These include river tables, artwork, prototyping, casting & molding. It is also suitable for creating three-dimensional objects, such as sculptures and molds.

Can I Use Deep Pour Epoxy as a Top Coat?

Deep pour epoxy is not recommended for thin layers. It it will take longer for a Deep Pour epoxy to cure in thin layers. For a durable and long-lasting finish, it is recommended to use a Flood Coat or Countertop epoxy as a topcoat over the deep pour epoxy.

Properties of Slow Cure Casting Epoxy Resin

Slow Cure Casting Epoxy Resin is specially formulated for thick pours. Making it an ideal option for deep pour projects. It has a low viscosity, allowing it to flow easily and fill in voids and imperfections. It also provides extended pot life, allowing for more extended work times. A controlled exothermic reactions to avoid cracking, shrinking, or overheating.

FAQs

Q: How long does deep pour epoxy take to cure?

A: Deep pour epoxy can take up to several days to cure completely, depending on the thickness of the application.

Q: Is deep pour epoxy food safe?

A: Deep pour epoxy is generally considered safe for use in food contact surfaces. It is recommended to use a food-grade epoxy to ensure safety.

Q: Can I add color to deep pour epoxy?

A: Yes, you can add color to deep pour epoxy using pigments designed for use with epoxy resin.

Q: Can deep pour epoxy be sanded and polished?

A: Yes, deep pour epoxy can be sanded and polished to a high gloss finish, providing a smooth and level surface.

Conclusion

Deep pour epoxy resin is an innovative material that allows for thicker applications than regular epoxy. It is an ideal choice for large-scale projects that require several inches of thickness, such as river tables, bartops, countertops, and flooring. While deep pour epoxy can be used for thin applications, it is essential to use the appropriate epoxy for the desired thickness. Slow Cure Casting Epoxy Resin is an ideal option for both thick and thin pours, providing extended pot life and controlled exothermic reactions. With this information, you can choose the best epoxy for your project, ensuring a beautiful and durable finish.

It is essential to test the result of a block of 4″x 4″x 4″ to validate if your resin is a deep pour system. This will save you time and money in the long run, as poor results on a larger project can have disastrous consequences. Make sure to choose a high-quality deep pour epoxy system that meets your needs and requirements, and provides clear information on the thickness and mass you can pour up to. For more information on our products and to read our latest blog on epoxy resins, visit www.chillepoxy.com/blog