Formulating Epoxy Resin Without Nonylphenol

Formulating Epoxy Resins Without Nonylphenol. Epoxy resins are cured with amines into polymers possessing network properties that can be adjusted, through knowledgeable formulation, to fulfill a wide array of end-product requirements.

During the last decade, the Epoxy Decoupage Coatings dedicated to wood workers and craft makers have gone through significant developments to improve ease of use and handling:

- More convenient & forgiving (less critical) mixing ratio;

- Better cure profile in wider range of conditions (air temp. & R.H.), along with reduced surface sweat and blush;

- Improved “water like” colour and clarity;

- Lower shrinkage & enhanced post-cure relaxation, enabling casting thicker than ever before, without cracking nor delaminating.

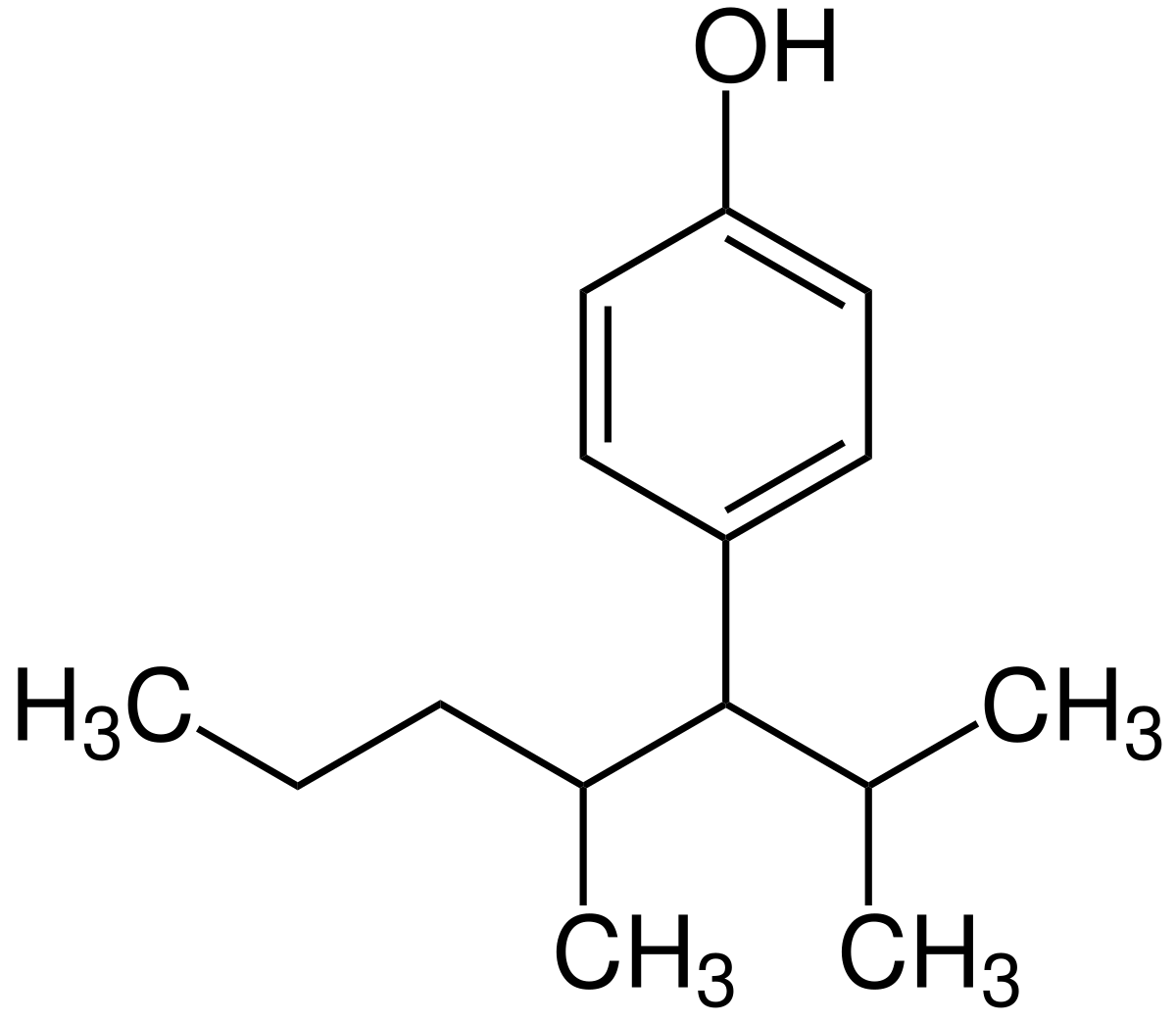

On route to achieve these properties within the specifics of today’s epoxy technology, being versatility or constraints, it has been common practice among formulators to use amine & adducts, filled as needed with non-reactive compatible materials, to adjust mixing ratios and enhance cure at the same time. Nonylphenol (NP) and Benzyl Alcohol (BA) being the most popular in that respect, since they are miscible in all proportions with both epoxies and amines, while each possess a hydroxyl group promoting cure.

However since chemistry is always a compromise (welcome here to the ones who not know yet), their “drawback” is that they are not chemically linked into the polymer network and may eventually leach out of the end-product through its life cycle. Inasmuch as the reactive materials cure into a non hazardous body as a whole, the “free” components entrapped in the matrix keep their hazardous nature and might pause a treat to the end-user that would be exposed to them while in contact with the end-product, if and when, they actually leach out.

Formulating Epoxy Resin Without Nonylphenol

We, at Polymeres Technologies INC, believe that this undesirable behavior should be minimized and avoided as much as feasible for the safer use of the end-product, and also for improved dimensional stability with time as leaching would cause shrinking. In addition, we observed that under certain conditions, NP and BA may affect clarity and color, which is detrimental in thicker transparent sections.

To alleviate these side effects, our approach has been to use and blend novel “clear water like” low viscosity polyamines allowing for stoichiometry adjustments to reach convenient and “somewhat forgiving” 2:1 to 1:1 resin to hardener ratios, with “built in” backbone compensation. Hence, Polymeres Technologies INC eliminate the amount of non-reactive components in its entire CHILL EPOXY™ line of premium epoxy resin products (Epoxy Decoupage) to levels 0%, compared to levels seen before as high as 30 to 40% with NP and/or BA.